Driven cast in-situ (DCIS) piles are constructed by driving a closed-ended hollow steel or concrete casing into the ground and then filling it with concrete.

Common uses

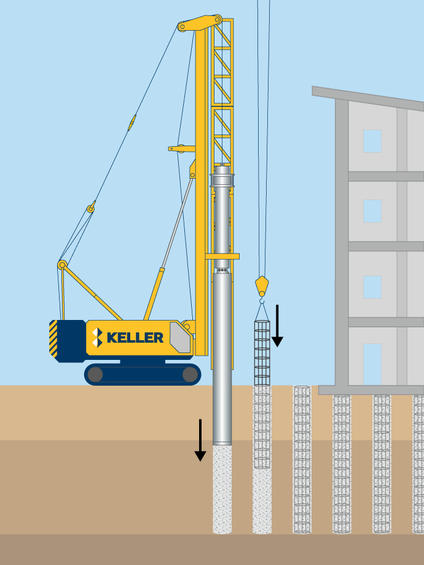

Process

The 25mm thick heavy steel tube is driven with the end closed by a steel shoe. On reaching the required driving resistance, a full length cage is lowered in to the tube and filled with high slump concrete. The tube is then vibrated out leaving a shaft of concrete.

Advantages

Quality assurance

Keller has extensive experience with driven cast in-situ piles, evolving the technique to ensure that high quality standards are achieved at all times.

Driven cast in-situ piles are instrumented during the installation process to provide high quality records during the construction process. A robust testing schedule also demonstrates the high performance/quality standards achieved.